Construction and Job Site Serious Injuries

Construction and job sites pose a range of hazards that can lead to worker injuries. A list of some of the most common injuries at construction sites includes:

- Fall From Height

- Spinal Cord Injury

- Struck By Object

- Electrocution, Electrical Shock

- Caught In Between

- Trench Collapse

- Fire and Explosions

- Heat Stress

- Exposure to Harmful Chemicals

- Eye Injuries

- Cuts and Lacerations

- Loss of Limb

- Traumatic Brain Injury (TBI)

- Slips, Trips, and Falls

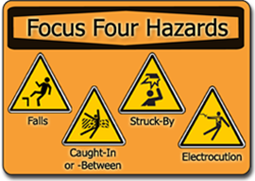

The “Fatal Four” or “Focus Four” in construction, which include Falls, Struck-by Object, Electrocutions, and Caught-in/between, accounted for a significant majority of construction-related deaths according to OSHA statistics from prior years.

Falls consistently remain the leading cause of fatalities in the construction industry in the United States, based on data from the Bureau of Labor Statistics. Construction consistently has a higher rate of injury, illness, disability and death compared to the national average for all industries. In 2021 a reported 5,200 work place injury deaths occurred, up from 4,750 in 2020. Not all injuries are reported, a Public Citizen analysis concluded that heat injuries and death from heat exposure could be 15-50 times more common than those reported.

To minimize risks, it’s essential that workers receive proper training, have access to and use the appropriate personal protective equipment, and that safety regulations and best practices are enforced at job sites. Despite an individual worker maintaining the proper training and safety guidelines, they can still be injured in preventable situations due to lapse of judgement or action by other workers and other contractors.

Common Job Site Injuries

These are how some of the more common construction and job site injuries occur

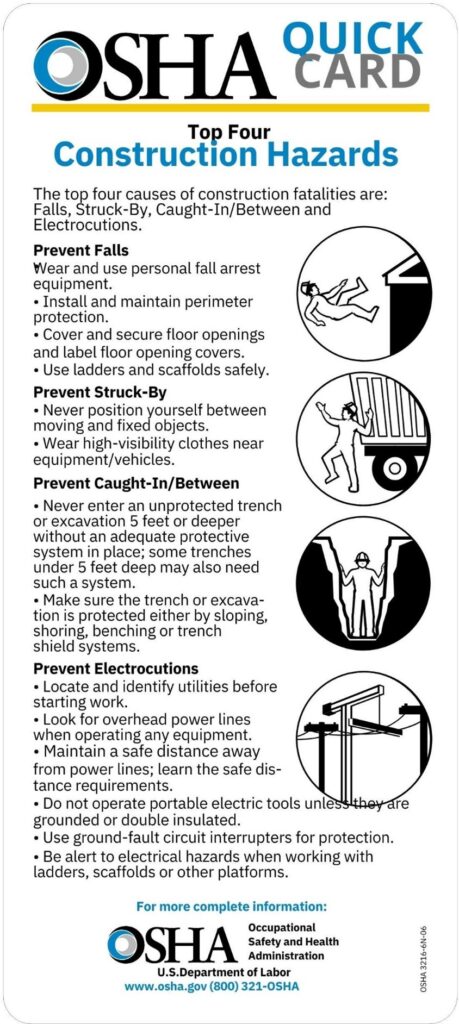

Falls from Height: Falls are the leading cause of fatalities in the construction sector. They typically occur from elevated areas such as ladders, roofs, and scaffolds. Examples include slipping off a roof, tumbling down a scaffold, or losing one’s balance from a ladder. To counteract this, OSHA has established extensive guidelines focusing on fall protection. OSHA’s standards (29 CFR 1926 Subpart M) mandate the use of fall protection systems like guardrails, safety nets, and personal fall arrest systems for construction workers working at elevations of six feet or more above a lower level. Training programs, aimed at recognizing fall hazards and the procedures to minimize them, are also emphasized.

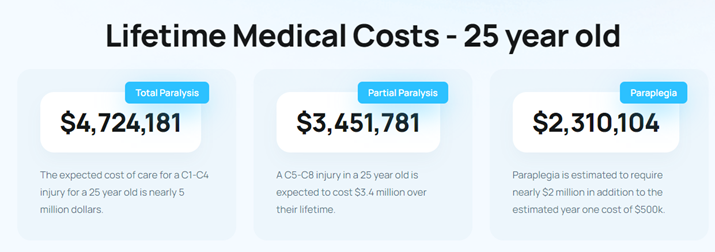

Spinal Cord Injury: An estimated 17,000 Americans survive a spinal cord injury each year, with many occurring at the job including at construction sites. Falls as mentioned above are a common source, but spinal injuries also occur from being struck by objects, slips, and crushing injuries. The cost of such a traumatic injury includes immediate hospitalization, short term care and rehabilitation, equipment such as wheelchairs, long term care, ongoing physical rehabilitation, and the need to replace lost wages and income. Injuries include partial paralysis, total paralysis, paraplegia and many other health and permanent conditions. Spinal cord injuries create one of the largest lifetime medical costs for workers.

Struck-by Object: These injuries happen when workers get hit by an object, be it a falling tool from above, a moving vehicle, or machinery in motion. The impact can lead to serious injuries or death. OSHA’s guidelines on this hazard stress on wearing protective equipment like helmets, high visibility clothes, and ensuring proper equipment operation and maintenance. Zone delineation to segregate equipment from pedestrian pathways is also encouraged.

Electrocution and Electrical Shock: Exposure to live electrical wires, malfunctioning tools, or contact with power sources can lead to electrocutions. The term electrocution means when an electric shock causes death, although many use the term to also include electrical shocks that are survived. Electricians and those working near electrical systems are most susceptible. OSHA’s Electrical Standard (29 CFR 1926 Subpart K) outlines safety standards for installations, safety requirements, and the utilization of equipment. Ground-fault circuit interrupters, proper grounding methods, and regular equipment inspections are among OSHA’s recommended preventive measures

Caught-in/between: This entails scenarios where workers get trapped or compressed between two objects or machinery, often resulting in crushing. It can occur during equipment rollovers or when someone gets entangled in machinery. OSHA underscores the need for machinery guards, safety training, and clear protocols for machinery operation to mitigate these risks.

Eye Injuries: From flying debris to chemical splashes, the construction environment poses numerous risks to the eyes. Welders, for instance, may experience flash burns without proper shields. To protect workers, OSHA eye and face protection standards (29 CFR 1926.102) mandate the use of suitable protection equipment. This can range from safety goggles for jobs with flying particles to full-face shields when working with chemicals. Chemical exposure is discussion below. Training on potential eye hazards and the importance of protective gear is essential.

Exposure to Harmful Chemicals: Construction sites often house a myriad of chemicals, from dangerous solvents that can cause burns or other reactions, to dangerous products or material such as asbestos. Inhalation or direct contact can lead to respiratory issues, burns, immediate or long-term health problems. OSHA’s Hazard Communication standard (29 CFR 1910.1200) dictates that employers provide information and training about hazardous chemicals in the workplace. Additionally, the Respiratory Protection standard (29 CFR 1910.134) emphasizes the use of appropriate respirators when working in environments with harmful air contaminants. Employers are also required to maintain Safety Data Sheets (SDSs) for each chemical, ensuring workers are informed about handling, storage, and first-aid measures. Injuries from chemicals can have devastating life-time effects on the function of lungs, kidneys, the heart, and other organs. Disability and death can occur in either the immediate term from large exposures, or long term through long-term illnesses

Fires and Explosions: Combustible materials, gas leaks, or faulty wiring can be precursors to devastating fires or blasts. These hazards can lead to burns, respiratory injuries, or death. OSHA’s standards on fire protection (29 CFR 1926 Subpart F) outline the necessary precautions, such as maintaining proper storage of flammable materials, ensuring good ventilation when using volatile substances, and keeping fire extinguishers readily available and inspected. Employers are also urged to establish evacuation plans and conduct regular fire drills. New technology such as lithium-ion batteries, which can store large amounts of energy, are sources of fires both at job sites and at the home and may be installed at the location, within vehicles, or contained within battery powered equipment.

Heat Stress: Workers, especially new workers not accustomed to their environment, can be injured or killed by heat exposure. Older workers, obesity, pregnancy and other factors can combine to increase risk, and by occupation the most common industry for a reported heat death was in construction, followed by agriculture and mining. Heat stroke, heat exhaustion, syncope, kidney failure or injury and rhabdomyolysis are all possible when a worker is exposed to excessive heat and not given sufficient water, breaks and shade if working outside. Workers injured by heat is not limited to outdoor labor, workers in factories or on job sites that overheat are a large part of the total injuries and deaths each year.

To read more on heat stroke, heat death, and how heat injuries occur on the job site, visit our worker heat stroke page.

Trench Collapses: Engaging in excavation work comes with the risk of trench walls caving in, which can entrap and bury workers. Such collapses can be deadly due to the sheer weight of the earth. To protect workers, OSHA’s excavation standards (29 CFR 1926 Subpart P) stipulate specific protective measures. For trenches deeper than five feet, protective systems like shoring, benching, or trench boxes are mandated, unless the excavation is made in stable rock. Trenches 20 feet deep or more require that the protective system be designed by a registered professional engineer or be based on tabulated data prepared by such an engineer. Trench collapses, even of trench sizes below the height of the worker, can prove nearly instantly fatal or cause serious injuries.

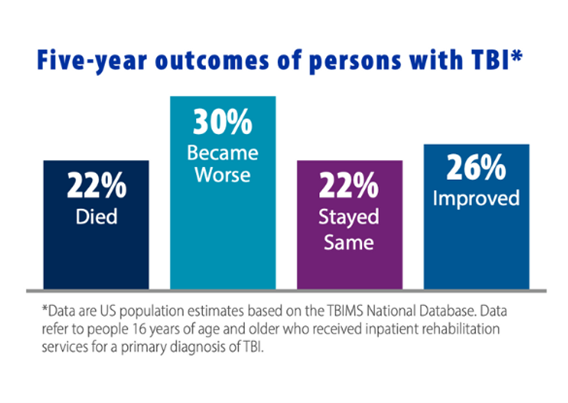

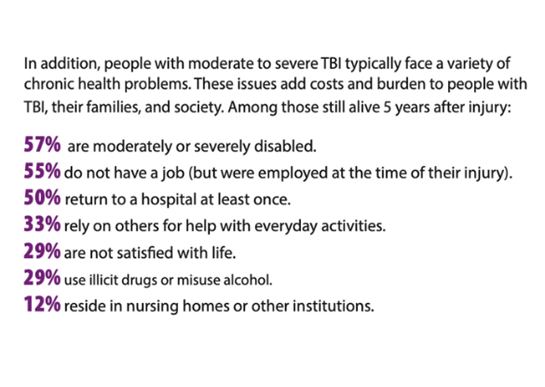

Traumatic Brain Injury: One of the most severe and life-altering injuries a construction worker can suffer is a traumatic brain injury (TBI). TBIs can result from blunt force trauma to the head, such as being struck by falling objects or by experiencing a serious fall. The implications range from mild concussions to debilitating cognitive impairments or even death. OSHA’s guidelines, particularly around fall protection (29 CFR 1926 Subpart M) and protection from falling objects (29 CFR 1926.100), can help mitigate risks. Hard hats are crucial in offering defense against potential blows to the head. Moreover, regular site inspections to identify potential overhead risks, coupled with safety training that emphasizes the importance of protective headgear are essential in minimizing brain injury occurrences. Workers who suffer a TBI have major impacts to both quality of life and future earnings, with the majority becoming disabled.

Cuts and Lacerations: In the construction world and other job sites, sharp tools and equipment, such as saws, knives, and nails, pose risks for lacerations or puncture injury. These injuries can range from minor cuts to deep wounds requiring surgery, resulting in permanent nerve injury, disability, or death. Using tools properly and ensuring they’re well-maintained is a minimum protective measure. Protective equipment including gloves can protect against injury and disability, and loss of fingers, hands or limbs. Other sources of injury include when sharp tools are not stored safely when not in use, or offered to those without proper training in their use.

Loss of Limb: Amputations or loss of limb can occur when limbs get caught in machinery, crushed between objects, or severed by sharp tools or equipment. Such injuries are not only physically devastating but also bear profound psychological and emotional impacts. OSHA maintains machinery and machine guarding standards (29 CFR 1910 Subpart O) provide guidance on safeguarding mechanisms to protect workers from the moving parts of machinery. This includes the use of barrier guards, two-hand tripping devices, and electronic safety devices. Regular maintenance and inspection of machines, coupled with stringent training on machine operation is vital. The emphasis is also placed on proper lockout/tagout procedures (29 CFR 1910.147) to ensure machinery is rendered inoperative during maintenance or when not in use.

Slips, Trips, and Falls: While similar to falls from height, these incidents pertain to accidents that occur on the same level due to unforeseen obstructions, wet floors, or uneven surfaces. They can result in sprains, broken bones, or head injuries. OSHA emphasizes the importance of maintaining clean and organized work areas (29 CFR 1926.25). This includes promptly removing waste and excess materials, marking and cordoning off wet areas, and ensuring proper lighting. Wearing appropriate footwear with slip-resistant soles is also crucial. Additionally, OSHA’s Walking-Working Surfaces standards (29 CFR 1910 Subpart D) encompass guidelines to ensure that all workplaces are free from recognized tripping hazards.

Third Party Liability – Negligent Third Parties at Job Sites

Construction sites are busy environments involving a variety of workers, companies, and entities. If an accident occurs, numerous third parties may have been negligent in causing or increasing the risk of the injury, depending on the facts and events in the individual case. Below is a list of potential negligent third parties:

General Contractors/Subcontractors: Contractors and subcontractors are primarily responsible for day-to-day operations on a construction site. Their negligence might involve failing to provide safety equipment, not following established safety protocols, or not adequately supervising their workers. For instance, if a contractor doesn’t enforce the use of harnesses at elevated heights, they could be held liable for fall-related injuries.

Property Owners: While they might not be directly involved in construction activities, owners have a duty to ensure their premises are safe. If they fail to inform contractors of known hazards, like weak floorboards or pre-existing electrical issues, they could be held accountable for resulting accidents.

Architects/Engineers: These professionals are responsible for creating designs that are safe and up to code. A structural flaw in a building design or not accounting for potential environmental challenges, contributing to an accident, can create liability by contributing to or causing the injury.

Equipment Manufacturers: Workers rely heavily on machines and tools. If a crane malfunctions due to a manufacturing defect, or a safety mechanism in a tool doesn’t perform as intended, the manufacturer may be responsible for the resulting injury.

Suppliers: Suppliers are expected to provide materials that meet industry standards and be safe for workers and customers. If a site uses substandard bricks that collapse, or are supplied paint with unexpected harmful chemicals, a supplier may be liable for harm caused.

Tool Manufacturers: Similar to equipment, tools must function reliably. A defective saw blade that breaks and causes injury can lead to the manufacturer being liable for damages.

Safety Consultants: Safety experts are specifically hired to ensure the safety of a site. If third parties tasked with this role overlook potential hazards, or give inaccurate advice leading to unsafe conditions, their negligence can result in liability for contributing or causing an injury.

Vehicle Operators: Construction sites often have heavy machinery and other motorized vehicles. Operators must be trained and attentive. If a bulldozer operator carelessly backs into a worker or a truck driver doesn’t secure their load properly, they and possibly their employers could be held accountable.

Utility Companies: Construction often necessarily involves working around gas, water, and electrical lines. If a utility company fails to properly mark these utilities or does not shut them off when needed, it could result in catastrophic accidents.

City or Municipal Entities: Government entities are in charge of issuing permits and ensuring that construction follows local regulations. If they grant permits without proper checks or overlook a significant code violation, they can be deemed negligent after an accident.

Inspection Agencies: Inspections are crucial to maintaining a safe job site. If an agency clears a site despite safety issues, like unstable scaffolding, they could be liable in the aftermath of an accident.

Crewing Agencies: Providing skilled labor is their responsibility. If they send workers who aren’t adequately trained for the job or fail to verify credentials leading to mistakes and accidents, they may be held liable.

Other Workers: On a bustling construction site, every worker’s actions can impact those around them. Careless behavior, like leaving tools on a walkway or not securing equipment, can endanger others, leading to potential liability.

Construction and Work Site Injury Law Firm

In any of these scenarios, the specific details of the incident and legal considerations play a crucial role in determining negligence and liability. To discuss a potential claim with an attorney, contact the worker injury lawyers at Schneider Wallace Cottrell Konecky for a free and private legal consultation.